In today’s era of smart manufacturing and adaptive design, Rorarm in tool has become a defining concept one that blends precision mechanics with advanced intelligence. At its core, Rorarm in tool represents the integration of robotic rotational arm systems within industrial tools and mechanical processes to achieve unmatched precision, efficiency, and adaptability.If you’ve searched for “Rorarm in tool,” you’re likely curious about how this emerging mechanical innovation enhances the design, control, and productivity of tools used in industries such as metalworking, construction, automotive assembly, and advanced robotics. Simply put, Rorarm in tool is the next evolution of machinery where tools no longer function as static instruments but as intelligent systems capable of adjusting their behavior in real time to deliver optimal results. This article takes a deep dive into Rorarm in tool technology, its principles, design, and applications. , it explores how mechanical intelligence is changing the way tools are built, used, and understood without relying on external sources, but through a conceptual and analytical approach that blends engineering thought with practical insight.

Overview of Rorarm in Tool Technology

| Aspect | Description | Industry Impact |

|---|---|---|

| Definition | Robotic rotational arm integrated within industrial tools for adaptive mechanical performance | Enhances precision, flexibility, and productivity |

| Core Function | Automatic alignment, torque control, and precision guidance | Reduces human error and machine downtime |

| Key Technologies | Sensors, motion control, AI-based calibration | Enables intelligent, real-time adjustments |

| Applications | Machining, assembly, material shaping, robotic tooling | Improves quality and consistency |

| Benefits | Speed, accuracy, and long-term sustainability | Drives innovation in smart manufacturing |

The Evolution of Tools in the Age of Intelligent Mechanics

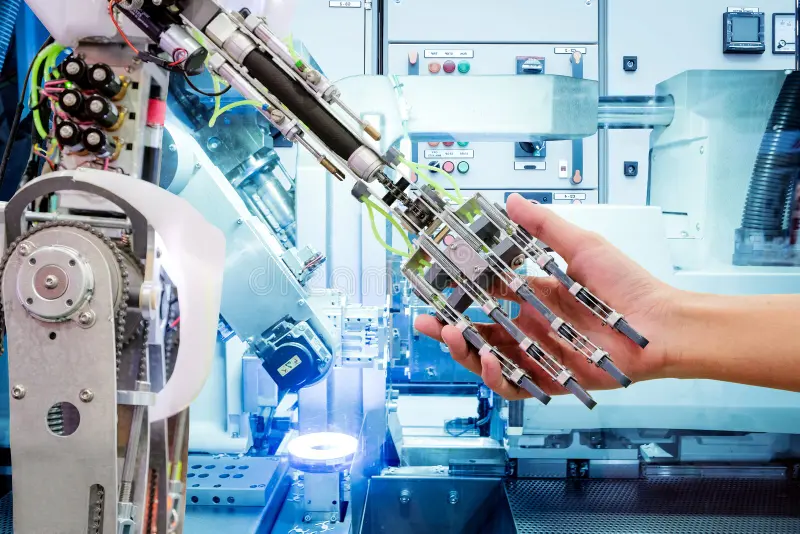

For centuries, tools have defined the human story from the first chiseled stones to the precision drills of today. But the leap from manual utility to mechanical intelligence represents more than just progress; it signifies a transformation in our relationship with machinery.Enter Rorarm in tool, an innovation born at the intersection of robotics and mechanical engineering. In traditional terms, a tool is an extension of human capability. In modern terms, with Rorarm integration, it becomes an independent system capable of analyzing, adapting, and optimizing itself. Imagine a torque wrench that adjusts its pressure dynamically to material density, or a cutting arm that detects heat variations and alters its movement to prevent material stress. These are not futuristic fantasies; they are the very essence of Rorarm-enabled tools systems that think, learn, and perfect their performance with each operation.This is the machinery revolution silent yet powerful, guided not by muscle but by logic.

Concept: What Is Rorarm in Tool?

At its simplest, “Rorarm” refers to a rotational arm mechanism a structure designed to move with flexibility and precision around one or multiple axes. When applied “in tool,” it signifies the integration of these arms within or as part of a tool system, enabling dynamic control over force, direction, and motion. But Rorarm in tool isn’t just about movement; it’s about intelligence. These systems use sensor arrays, AI-assisted controllers, and feedback loops to continuously refine their operation. In essence, the tool no longer relies solely on human control it co-manages performance with algorithmic reasoning.

Core Components of Rorarm-Integrated Tools

| Component | Function | Role in Performance |

|---|---|---|

| Rotational Arm Module | Provides multidirectional mechanical motion | Core movement and flexibility |

| Servo Motor | Converts digital signals into precise mechanical motion | Controls torque and speed |

| AI Controller | Processes data and directs motion | Enables intelligent decision-making |

| Sensor System | Detects pressure, temperature, and vibration | Provides feedback for calibration |

| Hydraulic/Electric Actuator | Executes physical movement | Transfers energy to the tool head |

How Rorarm Integration Transforms Traditional Tool Systems

Before Rorarm innovation, industrial tools followed linear, predetermined routines. A drill rotated at a fixed speed, a press applied uniform pressure, and a robotic arm repeated a programmed trajectory. With Rorarm integration, these systems evolve beyond repetition. They can:

- Adjust Motion Dynamically – The tool modifies its movement in response to real-time resistance or material irregularities.

- Predict and Prevent Errors – AI-based systems analyze wear patterns to prevent tool failure.

- Enhance Surface Finishing – Rorarm-equipped machines adapt to microtextures, producing smoother outcomes.

- Extend Tool Lifespan – Automated calibration minimizes mechanical strain and material fatigue.

In manufacturing, this translates to fewer defects, faster output, and a consistent level of precision unattainable by purely mechanical systems.

The Design Philosophy Behind Rorarm Tools

The philosophy behind Rorarm design is adaptive minimalism creating systems that achieve more through self-adjustment and less through manual intervention. Every element in such a tool serves two purposes: efficiency and awareness.

A typical Rorarm-integrated tool exhibits:

- Lightweight mechanical design for improved energy use.

- Modular arm configuration for versatile industrial applications.

- AI-driven balancing for self-stabilization under uneven load conditions.

- Sensor feedback optimization to maintain peak performance under stress.

This design framework turns mechanical engineering into a living art form a discipline where motion itself becomes intelligent.

Applications of Rorarm in Modern Industries

Rorarm-enabled tools are redefining industrial processes across sectors. Below are key industries leading the transformation:

1. Precision Machining

In CNC machining and metal fabrication, Rorarm tools provide micron-level accuracy, automatically compensating for vibration and material inconsistencies.

2. Automotive Manufacturing

From assembly-line tightening to robotic welding, Rorarm systems ensure torque precision and minimize mechanical drift.

3. Construction and Civil Engineering

Heavy-duty Rorarm drills and robotic excavation tools allow for accurate material cutting in unstable terrains.

4. Aerospace Engineering

Aircraft component production requires unmatched precision. Rorarm-based systems ensure lightweight materials are handled without stress or damage.

5. Renewable Energy Sector

Wind turbine maintenance and solar array assembly use Rorarm tools for on-site adaptability and remote operation under varying conditions.

Sectoral Adoption of Rorarm in Tool Systems

| Industry | Application | Resulting Advantage |

|---|---|---|

| Manufacturing | Automated assembly and machining | Higher precision and throughput |

| Automotive | Welding and tightening | Consistency and reduced defects |

| Construction | Heavy drilling and excavation | Structural accuracy and safety |

| Aerospace | Composite component shaping | Weight reduction and precision |

| Energy | Field assembly and maintenance | Sustainability and efficiency |

Rorarm Tool Advantages: Redefining Industrial Efficiency

- Unmatched Precision:

Sensors track every movement, correcting deviations instantly. - Operational Speed:

Real-time adaptability allows faster production without loss of quality. - Resource Optimization:

AI-driven motion reduces unnecessary power use and tool wear. - Enhanced Safety:

Predictive maintenance minimizes machine failure and human risk. - Sustainability:

Reduced material waste aligns with global energy-efficient production goals.

Rorarm tools are not simply mechanical enhancements; they are the cognitive evolution of industry.

Challenges and Limitations of Rorarm Tools

While promising, the technology also presents challenges:

- Complex Maintenance: High-precision sensors and circuits require specialized care.

- Cost of Integration: Advanced Rorarm units are capital-intensive.

- Cybersecurity Concerns: Digital components create potential data vulnerabilities.

- Skill Gaps: Operators must be retrained to manage intelligent systems.

However, these challenges are offset by the system’s long-term efficiency gains and environmental benefits.

Challenges and Solutions in Rorarm Integration

| Challenge | Impact | Potential Solution |

|---|---|---|

| High Installation Cost | Limits adoption by small industries | Introduce modular leasing systems |

| Technical Skill Gap | Reduces operational efficiency | Workforce retraining programs |

| Maintenance Complexity | Increases downtime | Predictive repair software |

| Data Vulnerability | Cybersecurity risk | End-to-end encryption systems |

Sustainability and the Future of Rorarm Tools

Modern industries must balance productivity with responsibility. Rorarm systems play a critical role in green manufacturing, helping reduce emissions through energy efficiency and precision optimization.

For example:

- Reduced friction means less energy loss.

- Self-calibrating systems minimize material wastage.

- Predictive performance reduces overproduction.

In the coming decade, Rorarm tools will likely define the foundation of eco-industrial machinery, merging environmental awareness with technological evolution.

The Economic Impact of Rorarm Tools

From an economic viewpoint, Rorarm systems redefine productivity metrics. Traditional measures like “units produced per hour” now evolve into “optimized operations per energy unit.” This shift introduces efficiency as a measurable asset. Large-scale adoption also stimulates employment in technical fields, as engineers, AI specialists, and maintenance professionals become vital to operational success. By improving throughput and quality simultaneously, Rorarm-based tools contribute to higher profitability and sustainability two goals once seen as contradictory.

The Philosophy of Human-Machine Synergy

At the heart of Rorarm’s development lies a philosophy: machines should complement, not replace, human creativity .Human engineers still design, guide, and analyze but Rorarm systems execute repetitive or precision-intensive tasks flawlessly. This balance of artistic design thinking and algorithmic execution defines the next stage of industrial craftsmanship.It’s not automation replacing humanity; it’s automation refining humanity’s tools.

Human and Machine Roles in Rorarm Tool Operation

| Aspect | Human Role | Machine Role |

|---|---|---|

| Design & Innovation | Conceptual creation and engineering insight | Execution and adaptation |

| Operation | Supervision and control | Automated task completion |

| Maintenance | Diagnosis and planning | Self-analysis and reporting |

| Improvement | Data interpretation | Performance feedback |

Technological Future: Where Rorarm Tools Are Headed

The next generation of Rorarm tools will merge with digital ecosystems forming connected machinery networks across continents. We can expect:

- Quantum-optimized control systems for microsecond-level precision.

- Biometric interaction, where tools respond to human gestures or neural signals.

- Predictive swarm robotics, enabling collaborative tool functions.

- Cloud-connected Rorarm ecosystems, ensuring synchronized maintenance across factories.

Such developments will push manufacturing beyond speed toward fluid intelligence, where tools become adaptive organisms in the industrial environment.

Conclusion

In every revolution, a quiet transformation reshapes how the world builds. Rorarm in tool represents that quiet, powerful change a convergence of motion and mind, of torque and thought. By embedding intelligence within mechanical systems, industries unlock the potential for precision without rigidity, efficiency without waste, and automation without detachment. The journey of Rorarm is more than technological; it’s philosophical. It’s about reimagining tools not as objects but as partners allies in a shared pursuit of excellence, safety, and sustainability.As we stand on the threshold of intelligent machinery, one truth emerges clearly: the future of industry belongs to tools that think, adapt, and evolve tools powered by the quiet intelligence of Rorarm.